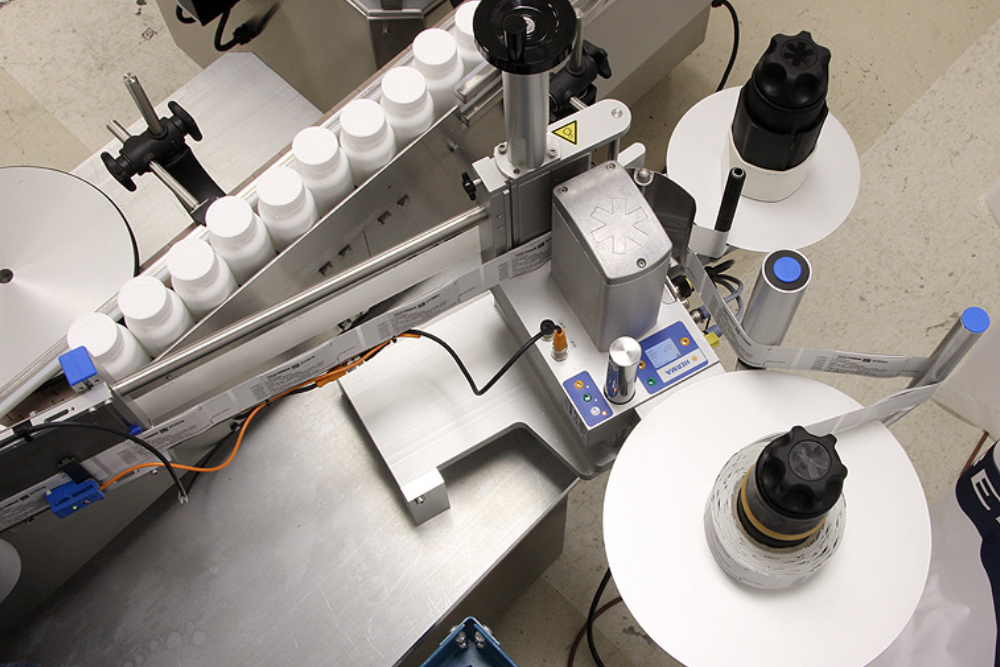

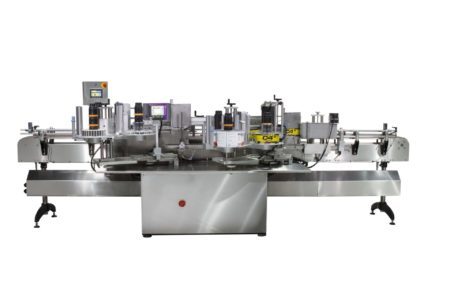

Notaris Wrap Labeler is a premium wrap labeler for applying pressure sensitive labels onto round containers.

Wrap-around labeling machines are designed to apply labels by rolling them onto the surface of the container. This maximizes printable space and allows you to include all relevant information on a single label. Wrap-around labeling machines can be used on glass, plastic, metal, and cardboard. They are ideal for companies that use round bottles or containers.

The Notaris Wrap Labeler is a versatile labeling machine capable of labeling everything from small vials to large jars with superior application precision. It’s an ideal solution for a wide variety of bottle labeling applications. This includes a three-point wrap pneumatic skew correcting system perfect for tall bottles and bottles with a distorted or uneven surface.

Features & Benefits of a Wrap Labeler:

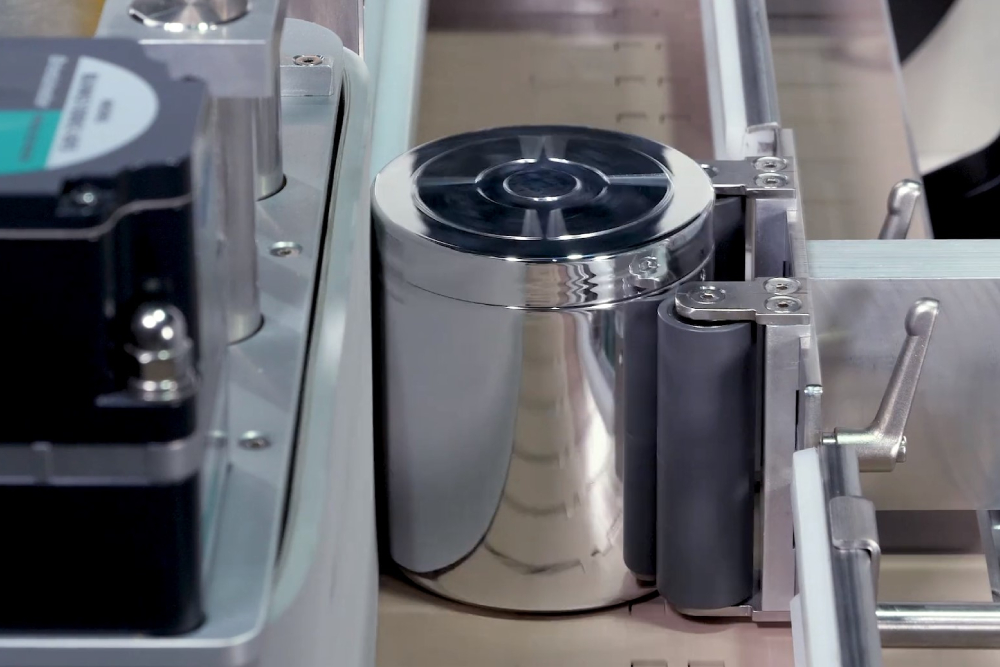

- Wrap label application with a wrap belt or upright rollers for unstable or uneven containers

- Herma 500 servo head

- Easily configured with infeed and outfeed turntables for a complete labeling solution or integration into a packaging line

- A comprehensive range of options for labels and containers to tailor labelers to your specific requirements

Specifications of the Notaris Labeling Machine:

- Speeds up to 100 cpm

- Multiple configurations available with a choice of labeling location

- Stainless steel conveyor with adjustable guide rails

- Allen Bradley PLC and color touchscreen

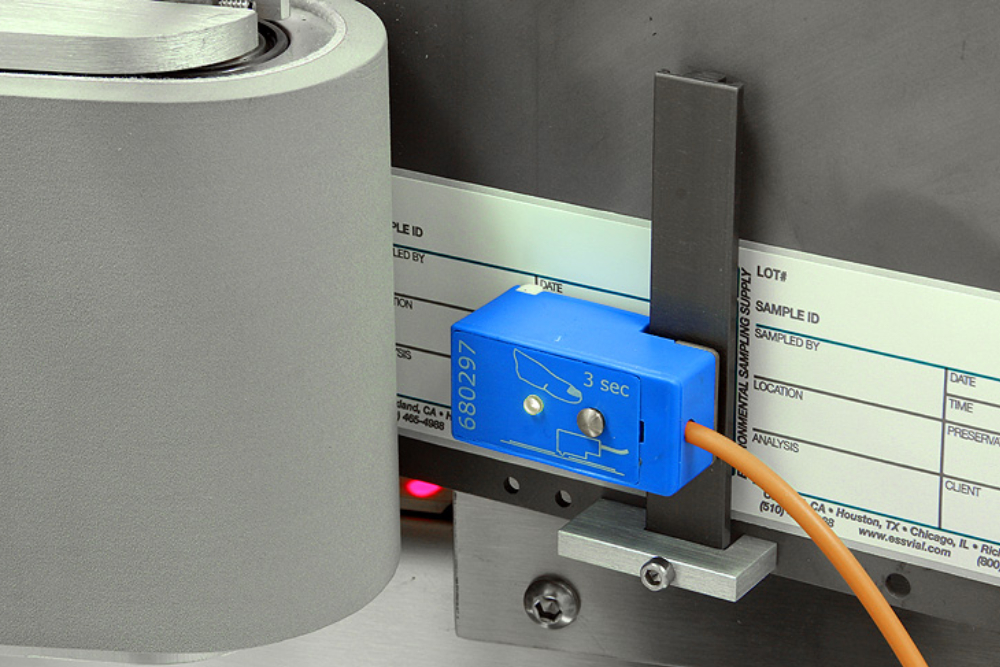

- Integration of lot code and expiration printing on the web

- Visual inspection of labels and printing

- Full serialization package available for track and trace requirements

Some Tips and Advice from ProSource:

Being responsible for labeling a product involves many decisions and choices to be made, but there are just four major steps to help you choose your labeling equipment. Comparing code technologies is essential as the strengths of each method must be matched with how well it will integrate with other equipment on the line. Here are best practices in label development and there are also common ways labeling projects can fail.

Download Brochure