Eliminate Downtime with Smarter Liquid Filling Machines

Downtime eats away at production. Every unexpected stop hurts production and eats into profit. Liquid filling machines are typically the first to feel that impact, and also the first place you can win efficiency back.

Here’s where to start tightening things up for smoother runs and fewer interruptions.

Understand Your Product Before Selecting Equipment

Before touching the machine, you should start by matching your filler to what you’re actually running. The viscosity of your product determines how it should be handled.

Thicker materials or those with particulates need pumps to move heavy or chunky products, like lobe or gear pumps. Thinner, freer-flowing products might only need gravity or piston filling. The better your liquid filling machines match the product, the less strain and downtime you’ll see.

Keep the Filling Line Clean, Controlled, and Leak-Free

Every drop counts. If your filler drips or splashes, you’re wasting product and cleaning time. Small leaks multiply fast when you’re filling at speed.

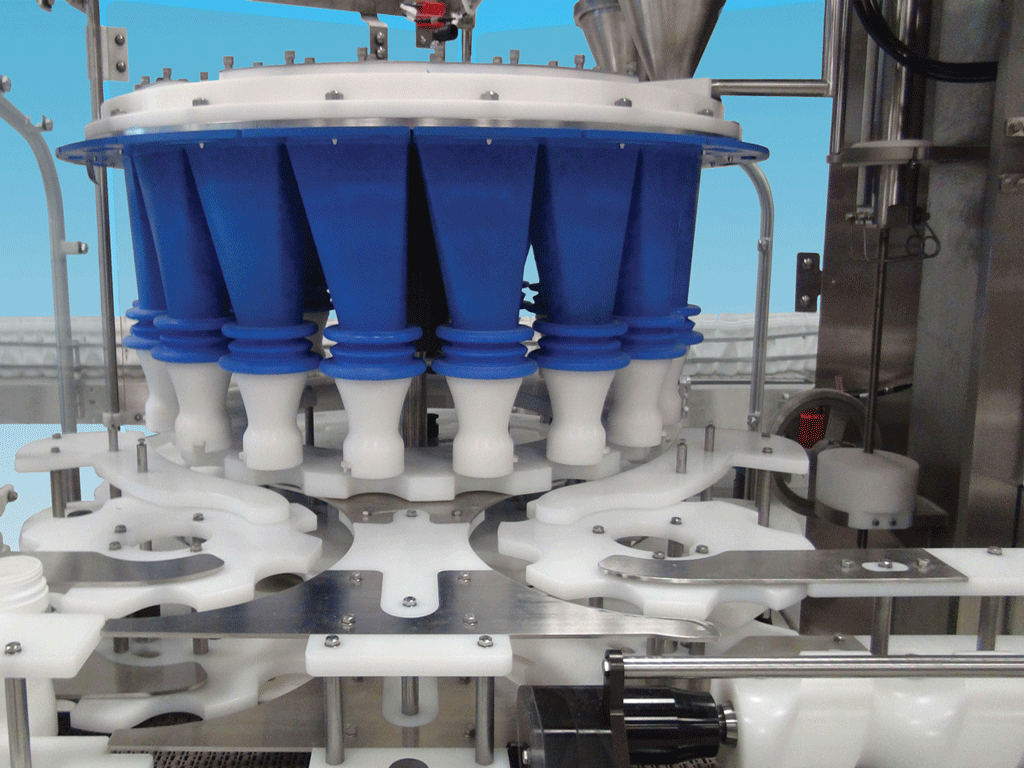

Adding drip-proof nozzles or shut-off valves is an easy win. And if product keeps splashing when the line ramps up, look at how the motion works. A switch from stop-and-go filling to a continuous rotary system can calm that chaos and keep your containers clean.

Give Products Space to Breathe

Fast liquid filling machines mean nothing if the rest of the line is not able to keep up. Your equipment will spend more time stopping and starting than filling if your conveyors and accumulation systems aren’t balanced.

Build in enough buffer zones and accumulation space so containers can queue up instead of stalling production. And pay attention to every conveyor handoff, as that is where unstable or oddly shaped bottles love to tip. A clean transition from station to station protects your output and your packaging.

Plan Changeovers the Smart Way

How often are you stopping to switch bottles or recipes? Every changeover is a time thief if the setup is not made for quick swaps.

Rotary liquid filling machines can be powerhouses, but they take longer to reset than inline systems. With a production schedule that changes frequently, you might be better off with flexible pumps like peristaltics that swap fast and sanitize easily. Sometimes a slower machine that never sits idle beats a fast one that’s always waiting to restart.

Prioritize Preventive Maintenance for Your Liquid Filling Machine

A neglected filler is a slow filler. It’s tempting to “run it till it breaks,” but that mindset burns hours and budgets. Routine maintenance on your liquid filling machines should be a part of the production plan.

Keep spare parts labeled and ready. Fix the little issues the right way rather than patching them mid-run. Use the correct tools for each container size to prevent wear and misalignment. The best-performing lines follow a structured maintenance schedule and stick to it.

Train Your Team, Protect Your Line

Liquid filling machines only perform as well as the people running them. Give your operators real training; ensure they can handle the machines and recognize early warning signs.

Set access levels so only trained personnel can adjust recipes or filling parameters, because one wrong setting can cause a cascade of problems down the line.

Talk to Each Other

Just as we value flow on the line, transparency between departments is equally important. A small change in one area, such as a new bottle or label, can ripple across the filling line.

Make a point to ensure that communication is open between packaging, QA, and production so that nothing catches you off guard during the run. Schedule a little extra time to test changes before pushing the line to full speed.

Choose a Filling Equipment Partner Built for Long-Term Reliability

Downtime costs lost product and breaks momentum. Liquid filling machines perform at their best when every part, from the machinery itself to the team running it, works in sync.

Bring BellatRx into the process and see how the right machines can change the pace of your floor. Connect with our team to see how a stronger partnership can keep your product consistent and your downtime under control.