Bottle Unscramblers

Bottle Unscrambling and Sorting Equipment

Bottle Unscramblers and Unscrambling Equipment for round, rectangular, square and oval plastic bottles.

WHAT IS A BOTTLE UNSCRAMBLER?

A bottle unscrambler is a machine that sorts (unscrambles) and feeds bottles onto a production line conveyor belt system. There, they are filled, capped, labeled, and packaged for shipment or storage.

Bottle unscrambling equipment automates the entire bottle sorting process, eliminating the time and costs associated with manual labor — a cumbersome process that slows down productivity and can result in errors.

ADVANTAGES OF BOTTLE UNSCRAMBLING EQUIPMENT

Bottle sorting equipment is easy to use and integrates well with existing production equipment. It can be used with a wide variety of plastic and non-fragile bottles and containers and is a popular solution in the food and beverage, pharmaceutical, household, chemical, and cosmetic industries.

A key advantage of bottle unscrambling equipment is its flexibility. It sorts and organizes bottles and containers in a variety of shapes and sizes. Should a business need to produce new bottle sizes, a bottle unscrambler will be up to the task without the need for expensive new equipment or a retooled production line.

Bottle unscramblers are commonly used to sort containers for the following types of products:

- Bottled water

- Juice

- Soda and carbonated beverages

- Dairy products

- Detergents

- Cleaners

- Lotions

- Motor oil and car care products

- Hair care products

Without a doubt, the bottle unscrambler is a boon to efficiency and an integral part of any bottling operation.

WHAT TO LOOK FOR IN A BOTTLE UNSCRAMBLER

When you’re ready to add bottle unscrambling equipment to your facility, take the following items into consideration before choosing a machine.

- Necessary Speed. Bottle unscramblers are positioned at the front of the production line, so they need to be fast enough to keep up with other equipment to ensure uninterrupted operation.

- Container Size. Each bottle unscrambler machine has a hopper designed for specific bottle sizes. If you’re using bottles larger than your machine’s ideal capacity, output will be significantly slower.

- Container Design. The machine you choose should be able to accommodate the design of your bottles. Certain features — a container that is too soft, is difficult to orient dimensionally, or contains a design feature that might interfere with operation — can play into your decision.

- Installation. Finding a good location is important. Most production lines begin with the bottle unscrambler, but if you’re adding to an existing setup, large and bulky equipment, such as a liquid filling machine, might already be taking up that spot. Installing bottle unscrambling equipment right before a labeler is a convenient alternative for many.

Request More Info - Short Form

View Bottle Unscramblers Solutions

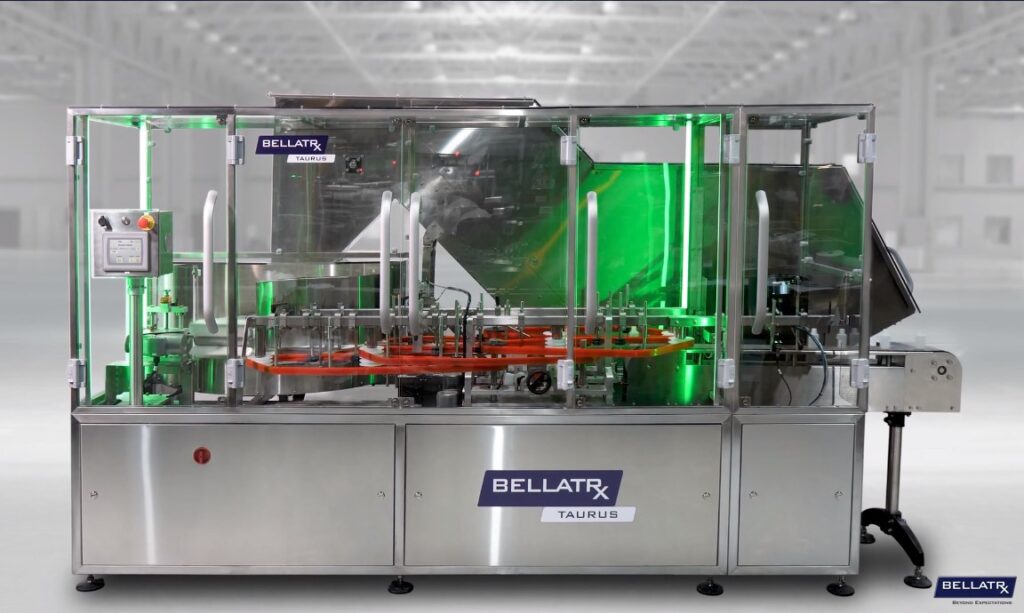

BELLATRX BOTTLE UNSCRAMBLING AND SORTING EQUIPMENT

Bottle unscramblers from BellatRx will help keep your bottles feeding to packaging lines at a steady rate. Our equipment can unscramble bottles of various shapes and sizes, capable of unscrambling round, rectangular, square, and oval PET, HDPE, PP, PS, and PVC plastic bottles with and without handles, with capabilities to run at speeds up to 200 cpm.

The Taurus unscrambler is simple to set up, easy to run, and boasts a changeover that is fast and tool-less.

Our bottle unscramblers serve dozens of industries, including: