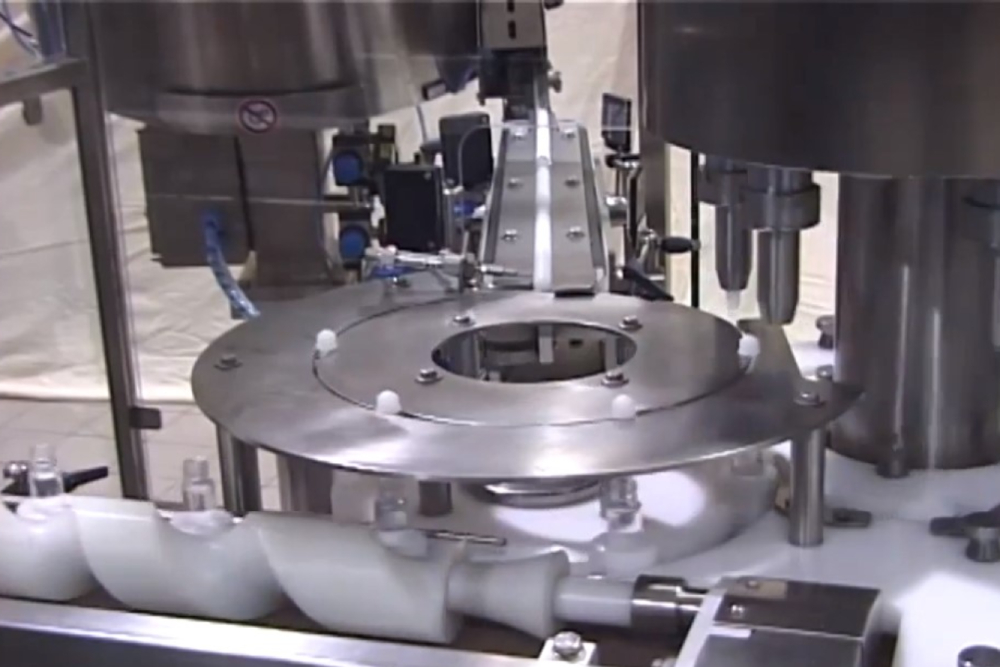

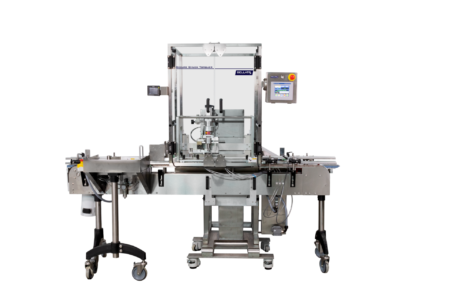

Our continuous motion rotary Capper is designed specifically for applications in the pharmaceutical, cosmetic, food and beverage industries. It caps and torques caps at high speeds without the risk of product splashing.

Contact Our Experts

Talk with our experts about your current line and identify opportunities for improvement.

Book a Meeting With Us

Schedule a 15-minute session to explore turn-key automation.

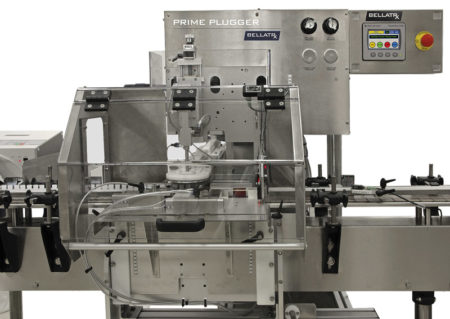

Rotary Filling & Capping Monobloc

Our continuous motion Rotary Capper is designed specifically for applications in the pharmaceutical, cosmetics, food, and beverage industries, as well as sterile areas. It caps and torques caps at high speeds without the risk of product splashing.

With options for four, six, or eight heads operating at speeds of 180 cpm to 250 cpm, our Rotary Cappers can handle a broad range of camps like screw-on, press-on, rubber stoppers, dropper tips, spray, ROPP, aluminum capsules, and crimp-on caps. Built with anodized aluminum and stainless steel for easy cleaning, all mechanical parts are separated from the working area and include a sanitary conveyor and bottle jam safety switch.

Features & Benefits:

- Four, six, or eight capping heads

- Infeed screw to provide proper bottle spacing

- Speeds up to 200 cpm

- Magnetic clutch torque control for each head (servo control available as an option)

- All contact parts made of 316 stainless steel

- Precise mechanical movements

- Available for sterile environments