We have an established track record in building equipment for specific environments with ISO Clean Room classification, ATEX, or Class 1 / Div 1 builds for hazardous environments where preventing ignitions sources or controlling particulate below pre-defined levels are needed.

When a special equipment build is required to fit within your room classification, whether it is ISO 5 or Class 100 clean room, we have compliant equipment in operation for numerous years. We clearly understand the implication for mechanical design, pneumatics, and controls to make the equipment compliant. Additionally, we have a range of machines which are build compliant to certain clean room ratings as standard.

When operating in environments where flammable product is packaged, equipment needs to meet classification of either ATEX or Hazardous Locations classification. At BellatRx we understand the requirements and have developed standardized kits to render equipment compliant.

- Reduce generation of particulates

- Single port filtered compressed air exhaust

- Laminar flow HEPA filtration units

- Elimination of sources of spark or ignition

- Purged electrical enclosures

- Intrinsically designed controls

Solvent – Chemicals – Class1 / Div1 – Magna Capper

Liquid Chemical – Diagnostics – Class 100 Clean Room

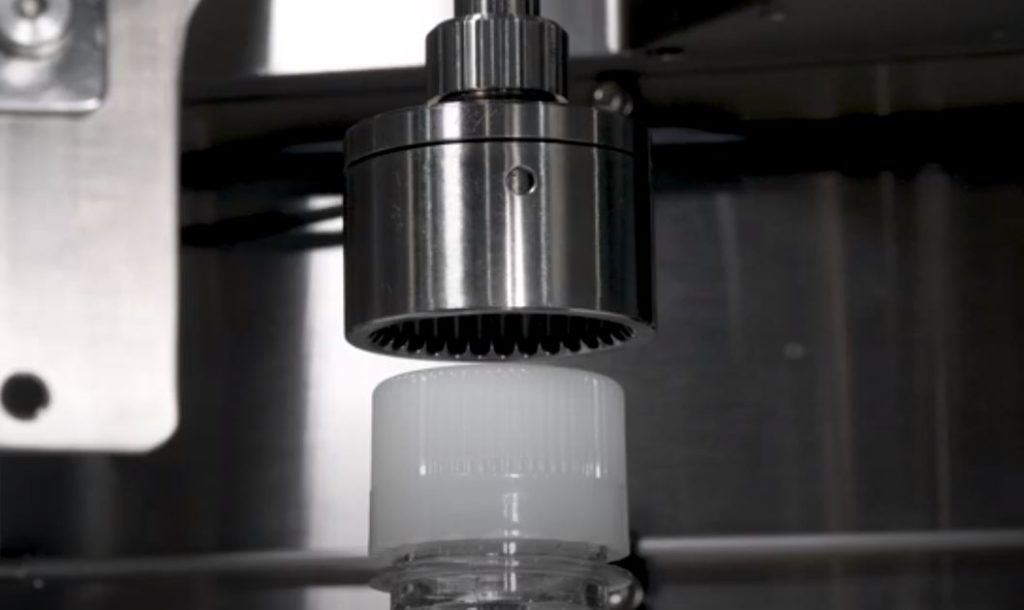

Spline Chucks

In order to prevent shedding from rubber material for capping chucks, one of the solutions could be a spline chuck. This chuck would have ridges which match with the ones on the cap. The stainless-steel spline chuck will not wear and will not shed. It is an ideal solution for clean rooms, especially when high application torques are required to prevent leaks.