Inspection of labels is a fundamental requirement for many industries to ensure compliance with industry regulation, to prevent errors, to ensure brand quality and to provide a legible package to the consumer.

Contact Our Experts

Talk with our experts about your current line and identify opportunities for improvement.

Book a Meeting With Us

Schedule a 15-minute session to explore turn-key automation.

Label Quality Inspection

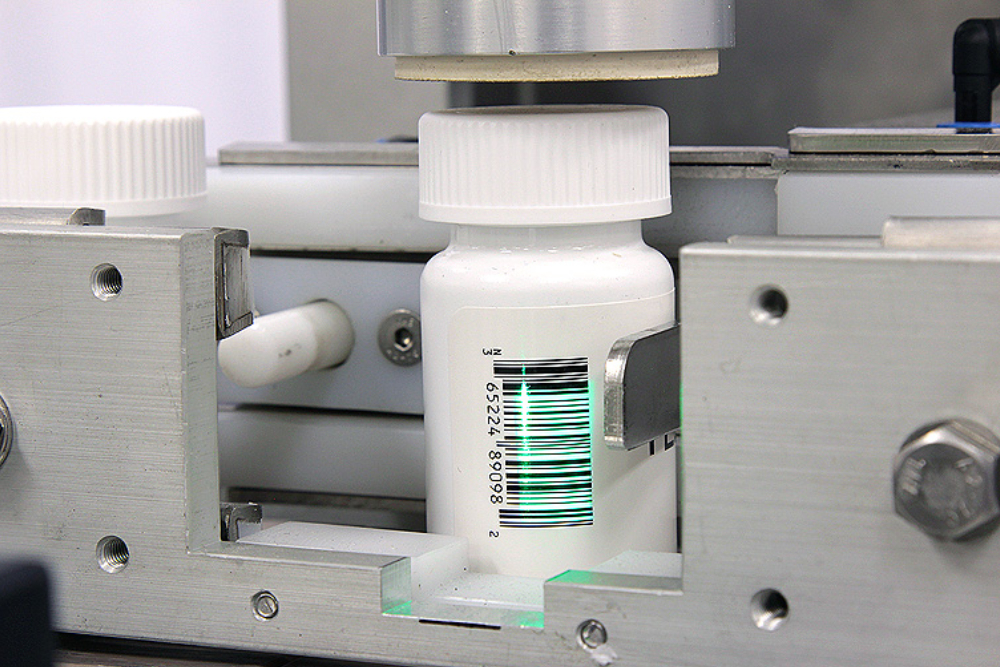

Our label inspection systems detect label defects or errors to meet quality standards. During the label application process, many defects are hard to detect due to the orientation of the belt and the curved surfaces of items. Quality inspections ensure product labeling is defect- and error-free. Machine vision systems with surface detection technology ensure labels are applied cleanly and squarely without wrinkles, air bubbles, rips, or other raised errors.

Features & Benefits:

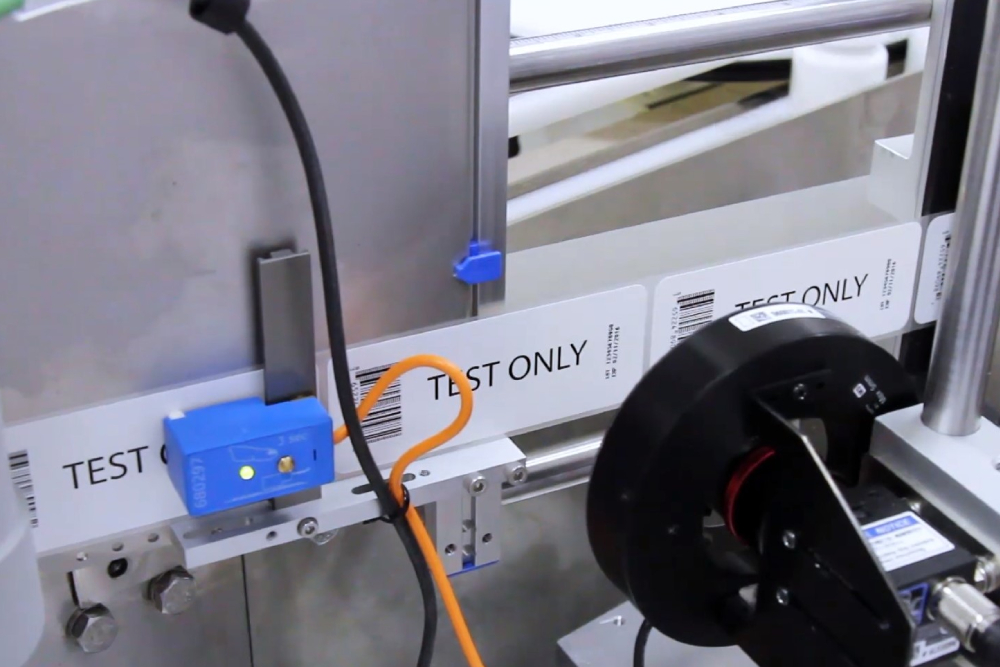

Label inspection can be set up in two locations:

- On the labeling arm before label application to the bottle

- After application to the bottle to ensure proper application

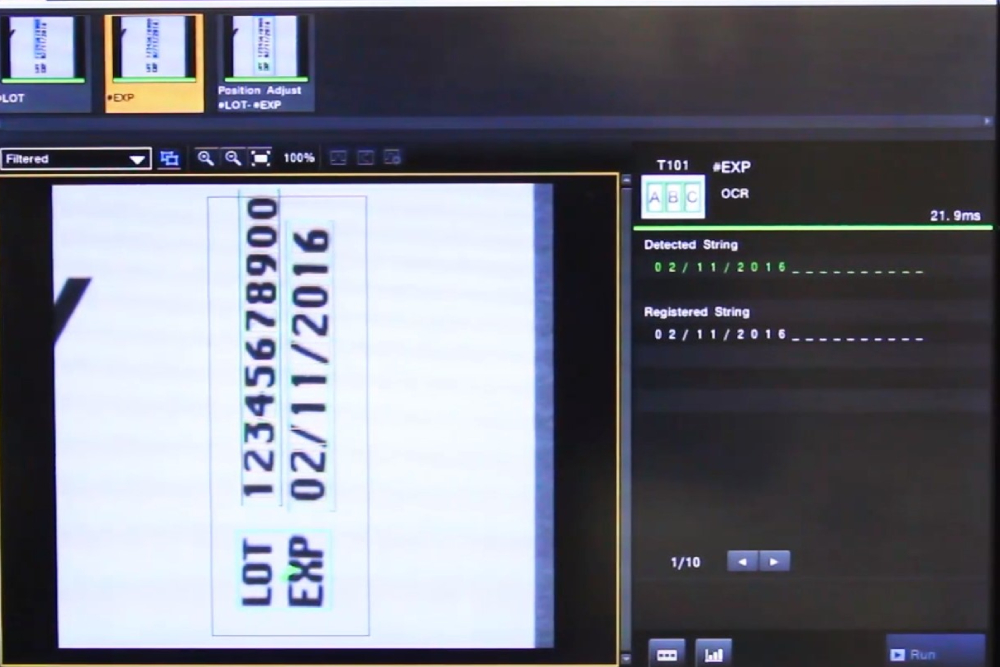

- Inspection is vision based and can detect the following characteristics

- Label placement and positioning in relation to a container feature

- Accuracy of lot code and expiration date

- Legibility of label print

- Barcode accuracy

- Serialization solutions to track and trace packages as required by pharmaceutical and other related industries