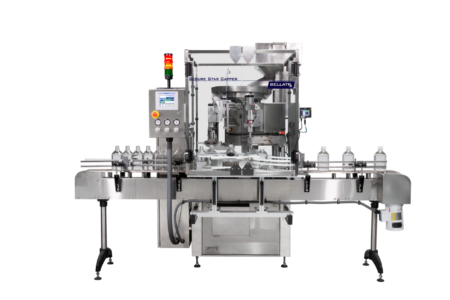

Secure Chuck Capper is an automatic in-line cap applicator that consistently applies and torques closures onto containers with accurate and repeatable application torque control.

Secure Chuck Capper is an automatic in-line cap applicator that consistently applies and torques closures onto containers with accurate and repeatable application torque control.

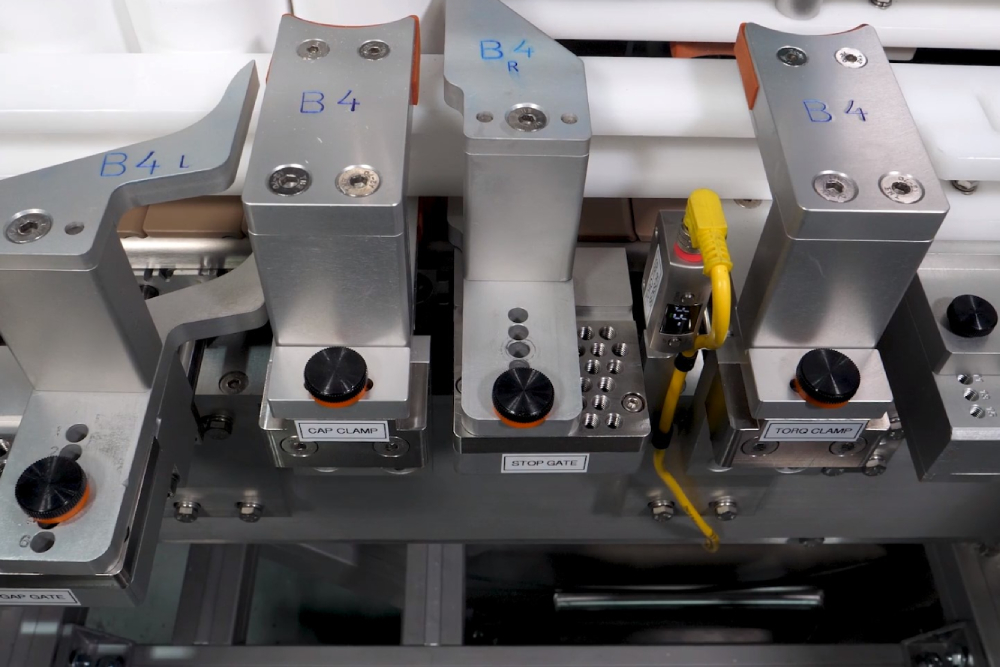

With an adjustable container indexing and clamping system, the Secure Chuck Capper is a versatile capping machine that can be mounted to any conveyor. With a chuck design, caps are applied squarely to the container, resulting in fewer skewed caps than spindle or belt cappers. Its small footprint and rugged construction make it the ideal cap applicator machine for the pharmaceutical, nutraceutical, cosmetic, and food and beverage industries.

Features & Benefits:

- Chuck design squarely applies closures to containers

- Reject rates typically 0.5% or less

- Quick changeover with minimal adjustment points

- No adjustments are required when running

- Allen-Bradley PLC and color touchscreen

Standard Specifications:

- Speeds up to 60 cpm

- 15 – 63mm closure range with a bowl

- 15 – 130mm closure range with elevator

- 0.5” – 8” by 12” high container range

- 5 – 80 in. lbs. application torque