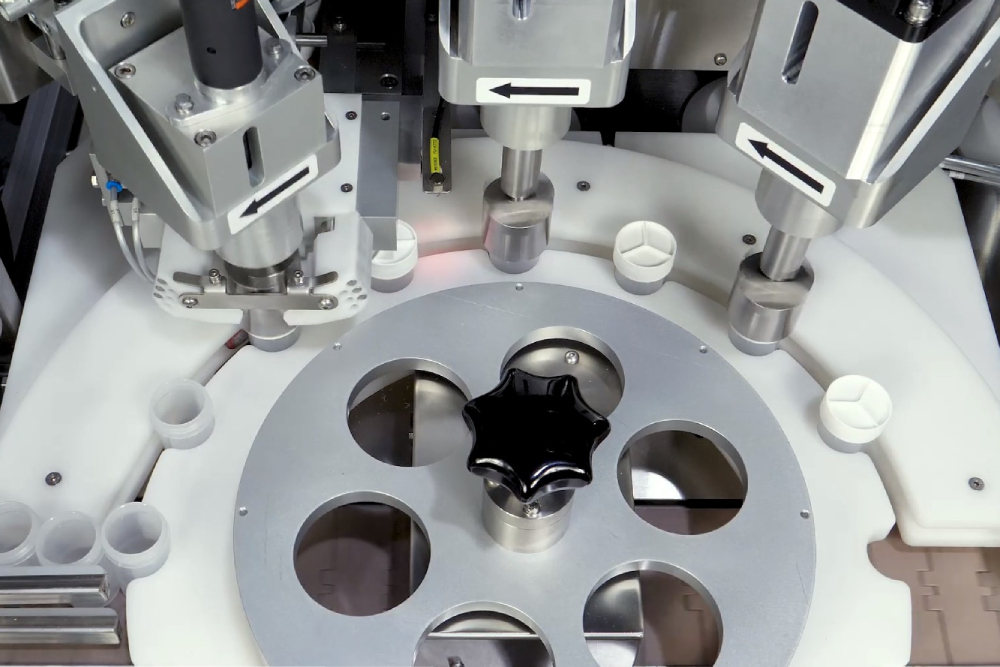

Secure Star Capper is an automatic high-speed starwheel cap applicator that consistently applies and torques closures onto containers with accurate and repeatable application torque control.

Automatic Rotary Capping Machine for Higher Speed Capping and Unstable Containers

Secure Star Capper is an automatic high-speed starwheel cap applicator that consistently applies and torques closures onto containers with accurate and repeatable application torque control.

This rotary capping machine features a precision starwheel indexer with two or three stations for accurate and precise capping of screw caps onto bottles that can be used in clean room environments. It’s ideal for food and beverage, pharmaceutical, cosmetic, and chemical applications.

Features & Benefits:

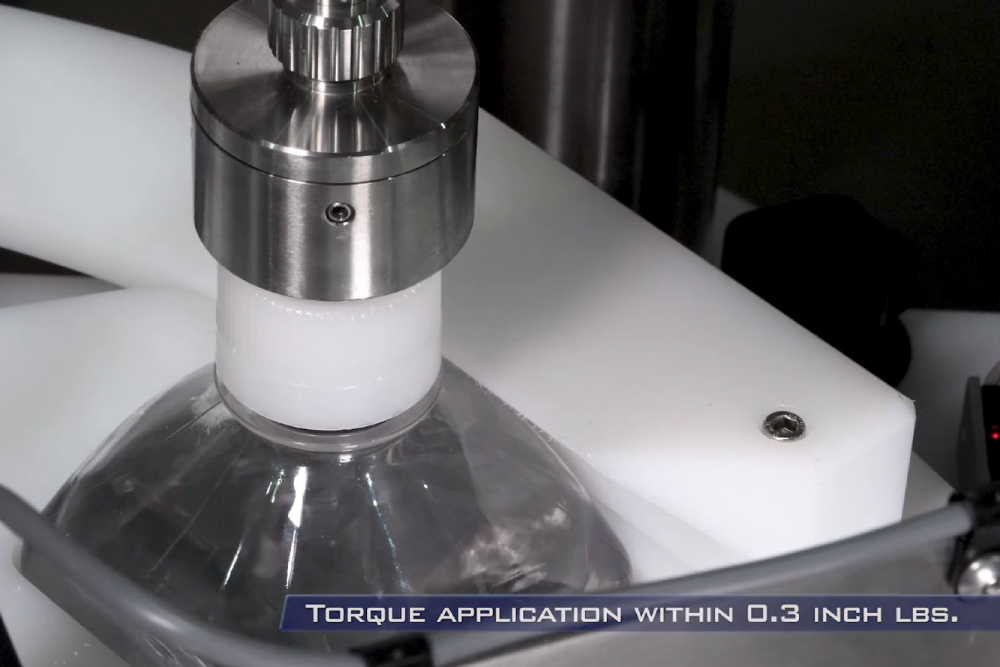

- Chuck design squarely applies closures to containers

- Reject rates typically 0.5% or less

- Quick changeover with minimal adjustment points

- Starwheel design ensures bottle and jar stability

- Allen-Bradley PLC and color touchscreen

Standard Specifications:

- Speeds up to 120 cpm

- 15 – 63mm closure range with a bowl

- 15 – 130mm closure range with elevator

- 0.5” – 8” by 12” high container range

- 10 – 100 in. lbs. application torque