Sleeve shrink tunnels play a pivotal role in the success of sleeving applications.

SHRINK TUNNELS

Sleeve shrink tunnels play a pivotal role in the success of sleeving applications.

HOT AIR AND STEAM SHRINK TUNNELS

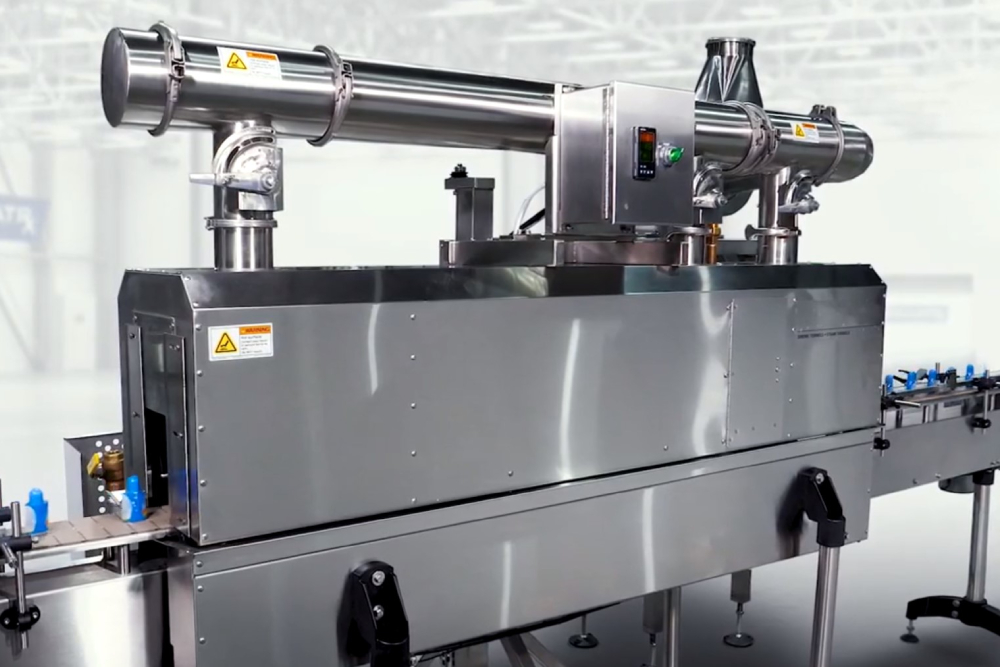

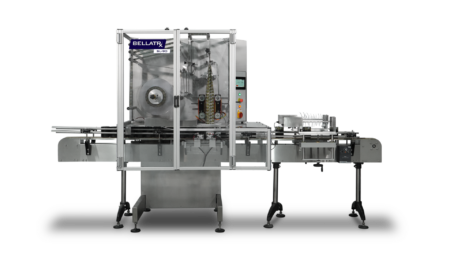

Shrink tunnels are temperature-controlled environments used to tighten shrink film that has been applied by a shrink sleeve applicator around products. Conveyor systems move packages through the oven, allowing for an even application of heat. The temperature of the tunnel needs to correspond to the shrink temperature of the film and provide an even distribution of heat to prevent image distortion on printed film. Conveyors are made from either large rollers or Teflon mesh belts for added stability.

Shrink tunnels are available in single- and dual-chamber formats. Single chamber shrink tunnels are perfect for lower packaging volumes that run lower pack speeds. Dual shrink tunnels are great for faster packaging speeds. Allowing for a more controlled shrink with variable chamber temperatures.

FEATURES & BENEFITS:

- Even heat distribution within the shrink tunnel

- Electric tunnels are ideal for non-printed film and neck band applications

- Steam tunnels are ideal for printed full-body sleeves and for uneven shrink requirements

- Special bottle handling can rotate the bottle while moving through the tunnel for even heat distribution

- Height adjustments stand with setup scales

- Heat management system to minimize heat loss