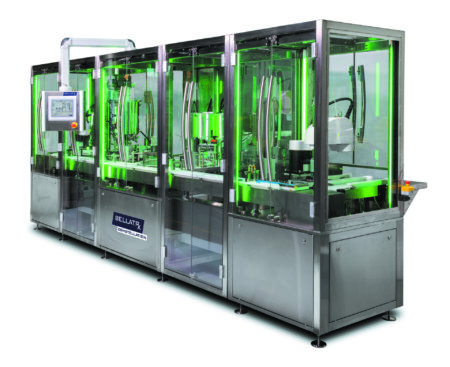

Aquarius Monobloc is a Fill-Plug-Cap-Torque system especially designed for applications in pharmaceutical, cosmetic, biotech, food, and e-liquid industries.

Contact Our Experts

Talk with our experts about your current line and identify opportunities for improvement.

Book a Meeting With Us

Schedule a 15-minute session to explore turn-key automation.

Aquarius Monobloc is a Fill-Plug-Cap-Torque system especially designed for applications in pharmaceutical, cosmetic, biotech, food, and e-liquid industries.

Features & Benefits

- Servo motion controller to synchronize operational stations

- Servo-powered 16-pocket starwheel with backing plate

- Speed of 55 cycles per minute for single index configuration

- Nozzle dive station with adjustable, servo-controlled stroke

- Plug & cap sorting system using 304 Stainless Steel electromagnetic vibratory bowls

- Plug & cap indexing servo-driven starwheel for pick-up stations

- Torque control using servo motor 2-30 inch lbs.

- Glow-light status beacons (green, amber, red) with white light illumination when guard doors are open

- Allen Bradley PLC Compact Logix series

- Allen Bradley HMI Panel View Plus 10″

There are several things to keep in mind when selecting liquid fillers to ensure the right fit for your application: Here are Nine Tips For buying liquid filling equipment.

A monobloc liquid filler machine is extremely versatile.

These fully automated liquid fillers perform a variety of tasks including filling, capping, stoppering, and labeling. They are fully integrated and can handle a wide range of containers, making them an ideal all-in-one solution.

The BellatRx Aquarius Monobloc automatic liquid filling machine utilizes a Fill-Plug-Cap-Torque system designed specifically for liquid filling applications in the pharmaceutical, cosmetic, biotech, food, and e-liquid industries.

Our Aquarius Monobloc liquid filler machine employs precise dispensing using a volumetric piston or peristaltic pumps, and diving nozzles. Servo-driven star-wheel indexes bottles and jars through the different steps to ensure precise liquid filling even when the volume differs from container to container. A compact footprint allows the Monobloc to fit in tight locations. It can be equipped with a HEPA hood, labeling, nitrogen purge, and several other functions for your process.