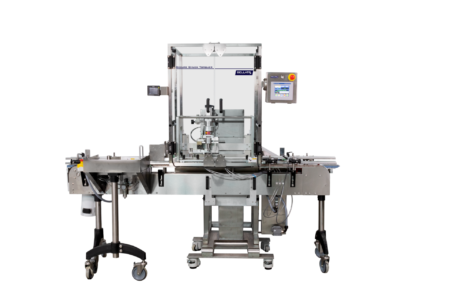

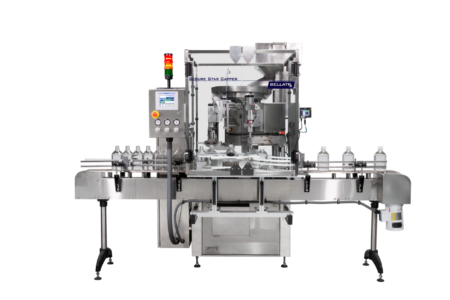

Servo, sensor, or vision-based cap inspection solutions ensure 100% cap inspection downstream of the capper.

Contact Our Experts

Talk with our experts about your current line and identify opportunities for improvement.

Book a Meeting With Us

Schedule a 15-minute session to explore turn-key automation.

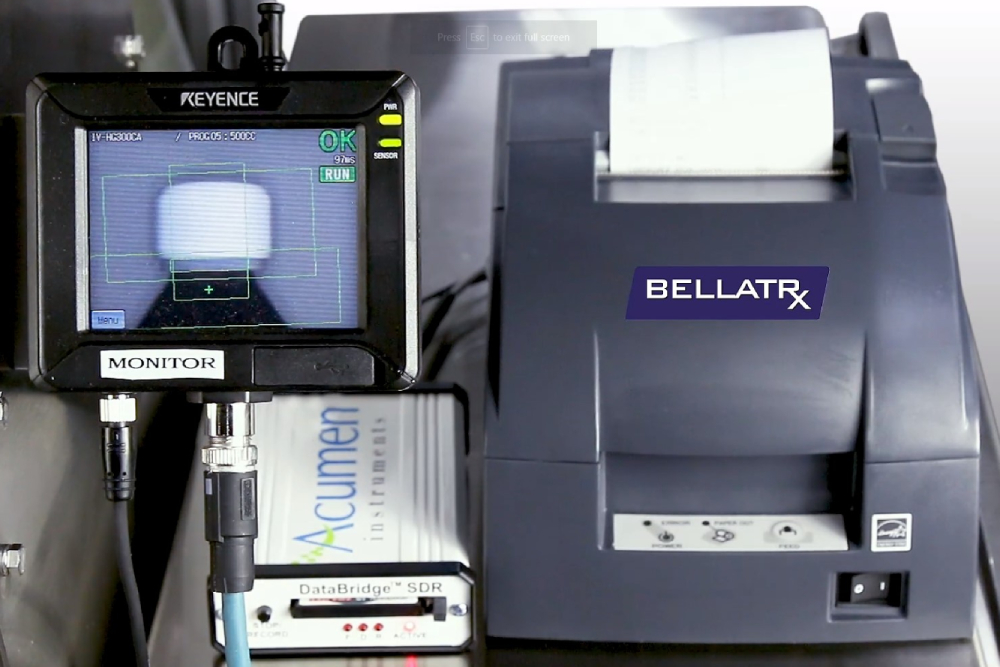

Sensor or Vision-based Cap Inspection in Lieu of In-process Checks

Servo, sensor, or vision-based cap inspection solutions ensure 100% cap inspection downstream of the capping machine.

The autonomy of your capper depends on the capper’s ability to produce low reject rates, and on the reliability of the cap inspection system to detect and reject out-of-spec caps. Inspection data can be stored, exported, or printed for easy reference at any time.

Features & Benefits:

- Cap presence inspection stops torquing station from engaging uncapped bottles

- High cap or skewed caps are detected and rejected from the system without operator intervention

- With servo versions, torque control ensures all caps are properly torqued to avoid leaks and to ensure proper induction seal

- Vision-based cap inspection can inspect for fill level with transparent bottles

- Vision inspection can compare the cap to a prominent feature of the bottle to avoid false rejects