Notaris Plus is the original all-servo 100% totally speed synchronized labeling machine with the most innovative ultra-fast recipe changeover system around.

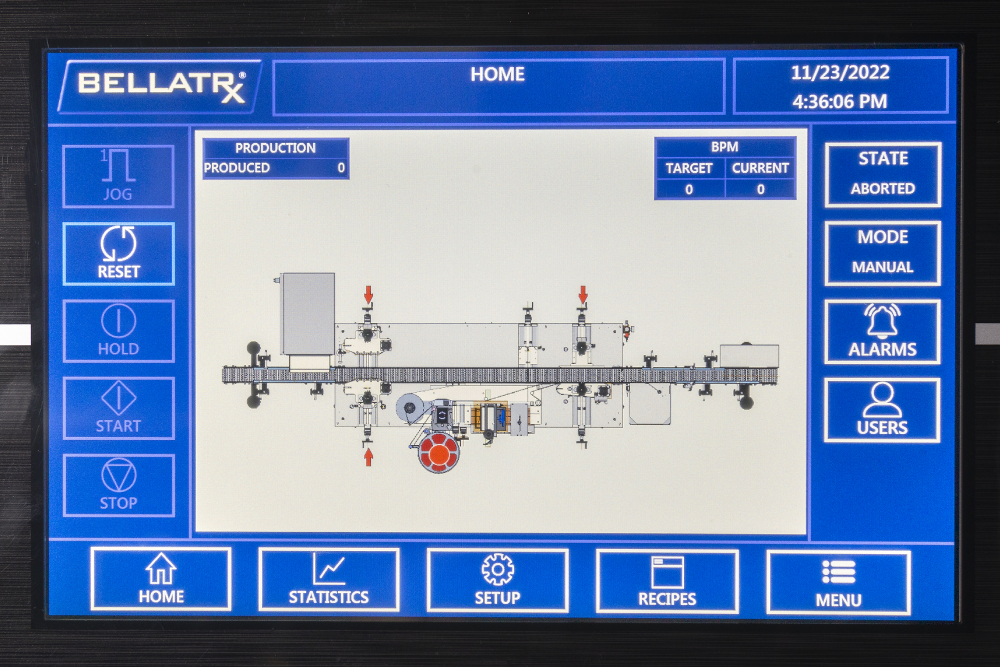

BellatRx is introducing the Notaris PLUS as the backbone to labeling automation in today’s labor reality. This is an upgraded and more intelligent version of our regular labeler that is technologically more advanced. Our new labeler is about technology and people. It has been designed with an operator interface that’s very simple to use and easy to understand and troubleshoot.

Features & Benefits

There are five significant areas in which the labeler provides value to our customers:

- Servo Drives setup and recipe creation; you need to enter the dimensions of the bottle and the label into HMI

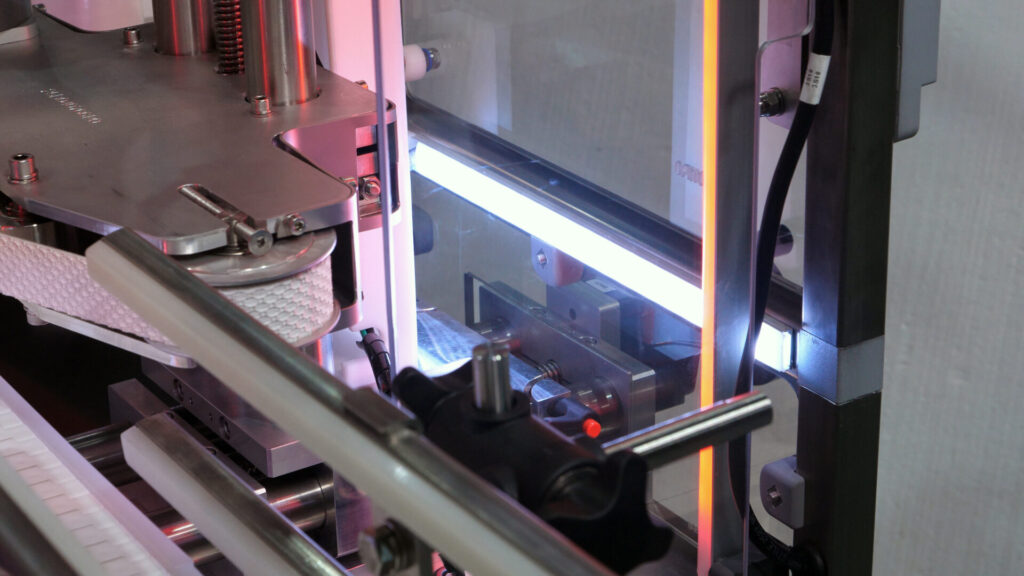

- Digital set points with electronic feedback tied into the setup screen. All mechanical adjustments have indicators with LED lighting which turns green when the operator is at the correct setpoint and red when they are not. On the HMI and the Siko indicators, arrows point to the direction in which the adjustment needs to be made.

- Setup Spot Light is another excellent feature notifying the operator when there is an issue with the assembly. The light strip is installed along the length of the machine. When setup is required on a particular assembly, the section of the LED strip in front of that assembly will light up to draw the operator’s attention.

- Fully guided step-by-step setup by the HMI: In the setup screen, the setup of a new format is divided by assembly, and a short animation or video per assembly would play to show the operator how to do the setup correctly.

- HMI is projected onto a portable hand-held tablet to view the setup and videos anywhere around the machine.

Specifications

- Speeds up to 100 cpm

- Multiple configurations available, including a choice of labeling location

- Stainless steel conveyor with adjustable guide rails

- Allen Bradley 10″ PLC and color touchscreen

- Integration of lot code and expiration printing on the web

- Visual inspection of labels and printing

- Full serialization package available for track and trace requirements

Some Tips and Advice from ProSource:

Being responsible for labeling a product involves many decisions and choices, but there are just four significant steps that help you in choosing your labeling equipment. Comparing code technologies is essential as the strengths of each method must be matched with how well it will integrate with other equipment on the line. Here are best practices in label development, and there are also common ways labeling projects can fail.

Download Brochure