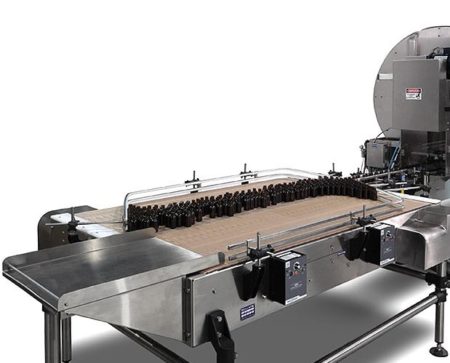

The Bi-Directional Surge Table is an accumulation system designed to take up excess capacity from upstream equipment when downstream equipment is down or running slower.

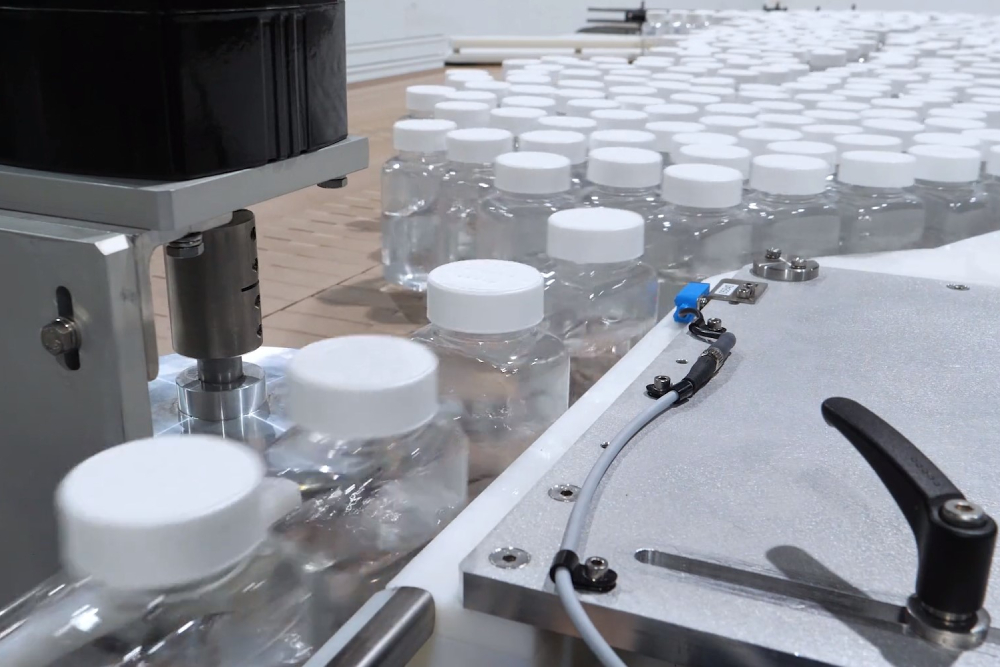

Surge Accumulation with Large Holding Capacity for Round and Non-round Containers

The Bi-Directional Surge Table is an accumulation table system designed to take up excess capacity from upstream equipment when downstream equipment is down or running slowly. This ensures your conveyor belt system operates at maximum efficiency and prevents unwanted bottlenecks and downtime.

Our bi-directional accumulation table allows for the packaging line to maximize its output at the end of a production run. The Bi-Directional Surge Table can accumulate round, oblong, square, and other odd-shaped containers, and then feed them back onto the line once the downstream conditions allow. All this without intervention from the operator.

ACCUMULATION TABLE FEATURES & BENEFITS:

- Production surge control an in-line accumulation

- Bi-directional table with minimal back pressure

- Handles round and non-round containers

- Intelligent bottle flow control logic

- Bottle flow diversion (manual or automatic)

STANDARD SPECIFICATIONS:

- Speed: up to 200 cpm

- Product range: up to 6″ diameter

- Dimensions: several standard sizes and configurations are available to fit your specific requirement and accumulation needs.

Some Tips and Advice from ProSource:

- Tips for more efficient package and product handling

- Proven tips for setting up conveyors on a packaging line

- Best practices for specifying and container handling equipment

- Best practices for buffering and packaging line design