View Our Liquid Filling Machine Solutions

Liquid Filling Machines Featuring Automatic and Semi-Automatic Filler Systems

BellatRx is a leading manufacturer for your liquid filling machine needs. When you have bottles or containers that need a liquid filling, you’ll want to ensure each vessel is filled quickly and accurately with the exact amount of liquid required. Your best bet for precision and speed is a liquid filling machine — but with a wide range of options available, knowing which one to purchase can be confusing.

BellatRx specializes in liquid filling machines for a variety of applications. Before making a decision, our liquid filler experts recommend examining the following aspects of your business.

- Liquid Characteristics. The type of filler you’ll need to successfully package your product depends on the viscosity of the liquid — its resistance to flow. Water flows more readily than a thicker fluid such as olive oil, so your liquid filling machine must have the capability to overcome any resistance. If your liquid contains particulates — fibers, seeds, or pulp — or is semi-solid, you’ll need special pumps and valves.

- Container Type. The type and shape of the containers you are filling will help determine what kind of liquid filling machine you need. Different materials have varying properties; plastic and aluminum are consistent in shape, while glass is less precise; this discrepancy must be accounted for to achieve uniform fill levels. Containers that are thinner, wider, taller, shorter, or contain non-standard caps and lids require special handling available with specific liquid fillers.

- Operational Needs & Constraints. The size of your facility and rate of production will dictate what kind of liquid filler is most efficient for your operation. Smaller businesses with limited space and tighter budgets might want to consider semi-automatic liquid filling machines, while bigger companies with high production rates and more extensive floor space will find automatic liquid filling machines most beneficial. Don’t forget to take future needs into consideration. Are you expecting strong business growth or expansion into a more diverse product line? Think about your upcoming liquid filling needs and plan accordingly.

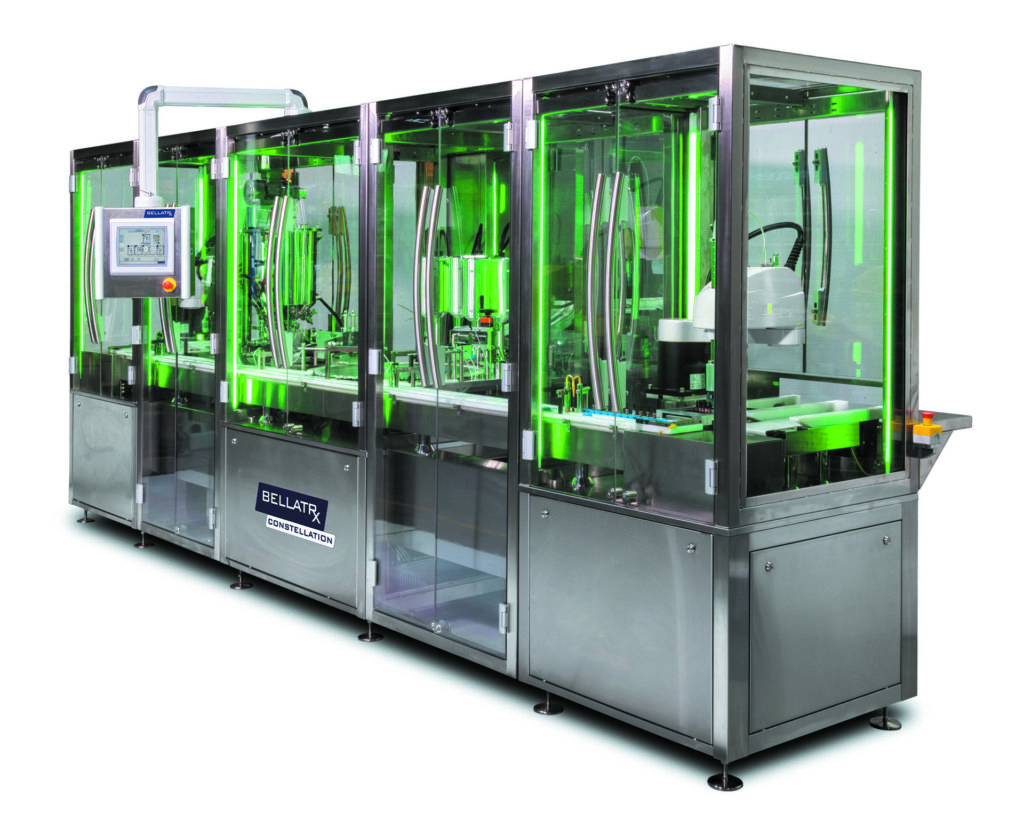

BellatRx carries a wide range of liquid fillers suitable for all types of products and packaging lines, from sterile food and pharmaceutical packaging to harsh chemical production. Ruggedly built and incorporating state-of-the-art technology, our liquid filling machines are designed for versatility and made to withstand extreme operating conditions. They are available in a variety of sizes and can be customized to meet your specific production needs.

We offer a full array of semi-automatic and fully automatic liquid filling machines capable of filling non-viscous and viscous liquids accurately and efficiently. Configurable units can be equipped with piston fillers, overflow fillers, pump fillers, and flow meter liquid fillers, among other designs. Our monobloc liquid filling system utilizes the most advanced servo-driven technology on the market today, giving our customers a competitive edge in the liquid filling industry.

Our liquid filling machines serve the following industries: