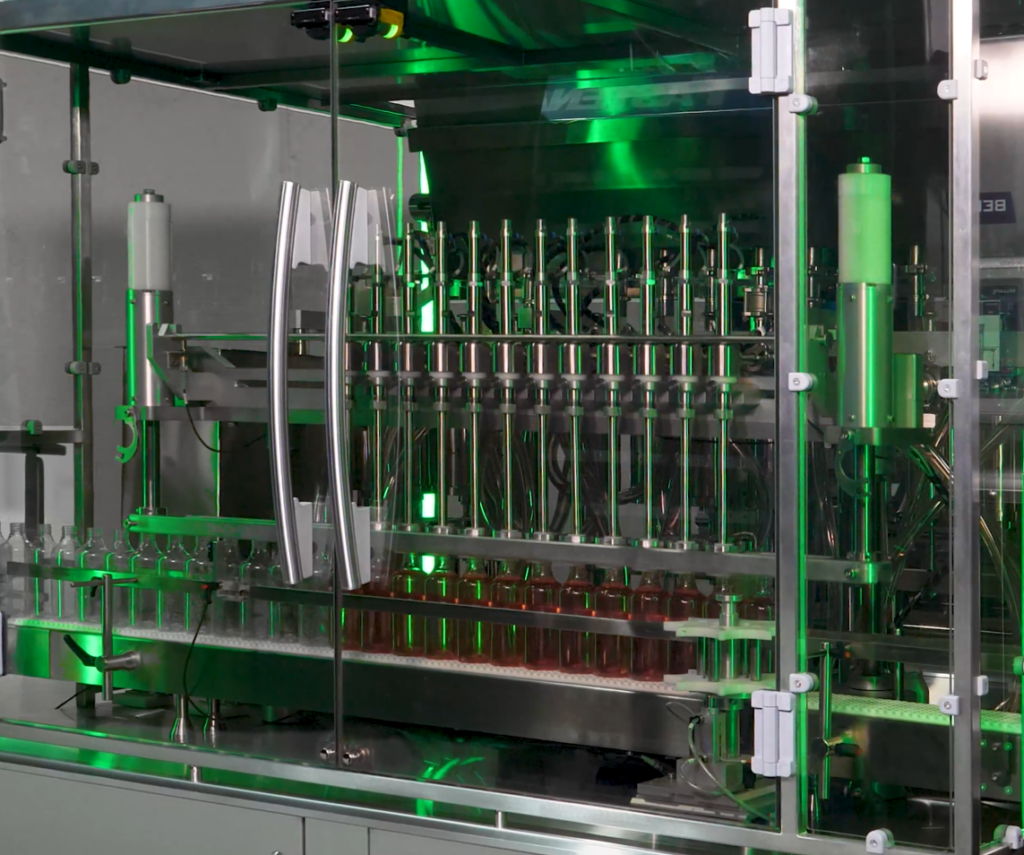

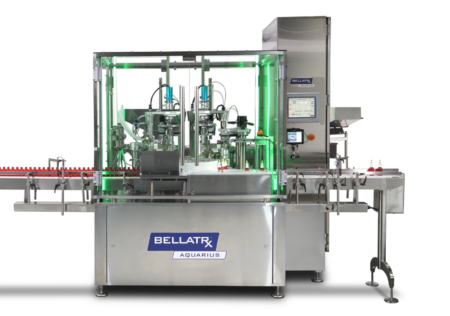

Our in-line fillers are available with 2, 4, 6, 8 or 12 filling stations for filling of liquids, creams, and hot products.

Features & Benefits:

- Available with standard conveyor or with pucks for unstable bottles

- Very fast and easy changeover of format size

- Docking filling station model available for fast change over of wetted path

- Servo-driven diving nozzles with bottom-up filling

- Servo-driven volumetric or peristaltic filling stations

- Inert gas purging stations can be incorporated into the fillers

- Conveyor incorporated into the filler with bottle indexing

Inline fillers are used in liquid filling applications to fill containers in a line. They are extremely versatile, able to handle a wide range of liquids and fill bottles of all sizes. Their efficiency, lower cost, and ease of use make them a popular choice for small to medium-sized operations.

Our filler packaging machine solutions offer versatility for a variety of liquid filling needs. They are available with two, four, six, or eight filling stations and can be used as a liquid filling machine, cream filling machine, or powder filling machine. They are ideally suited for liquid filling applications involving hot products.

There are several things to keep in mind when selecting liquid fillers to ensure the right fit for your application: Here are Nine Tips For buying liquid filling equipment

Download Brochure