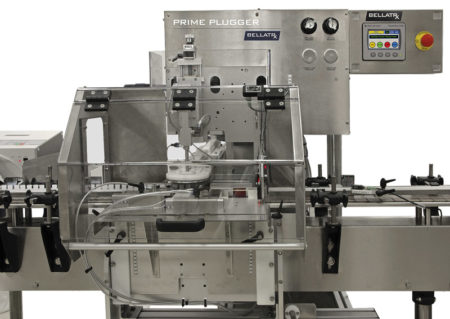

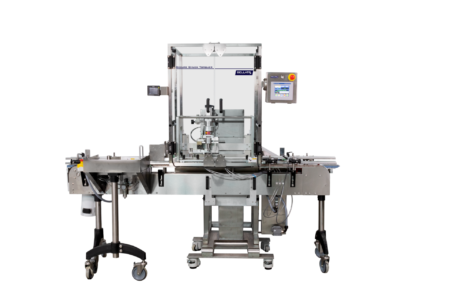

Prime Plugger is an affordable, automatic inline applicator that consistently inserts dropper tips or stoppers onto containers.

An Easy-to-Use Plugging Machine That Delivers Consistent Results

Prime Plugger is an affordable, automatic inline applicator that consistently inserts dropper tips, plugs, or stoppers onto containers at speeds up to 60 cpm.

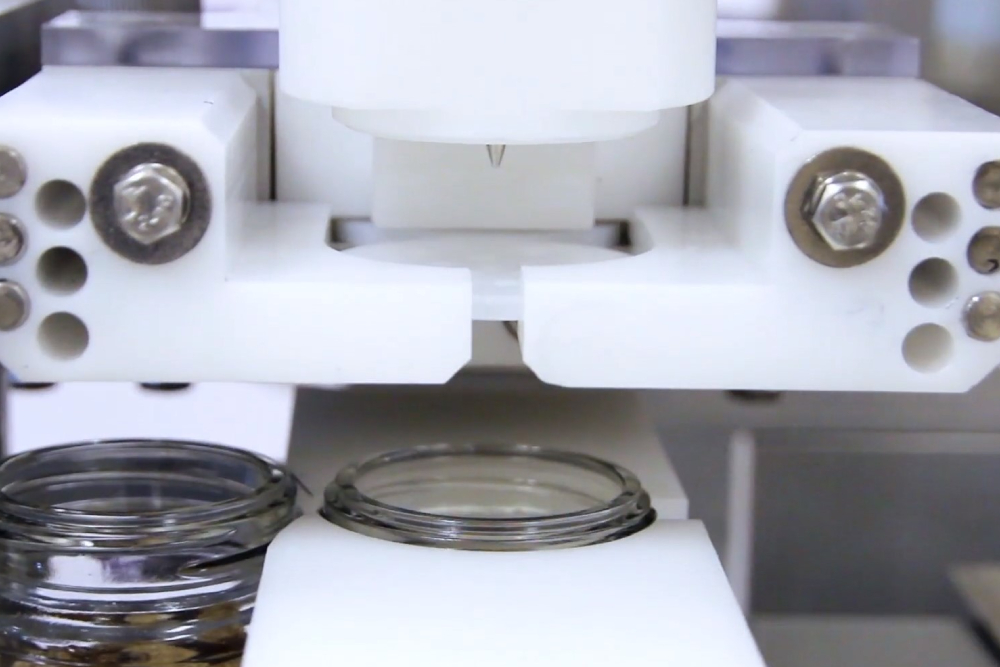

The plugging machine was designed to meet the unique requirements of plug application, which often necessitates applying plugs at angles conventional capping machines are unable to handle. Plug caps are typically made of rubber and are placed either inside the neck of the bottle or around the neck to securely seal the container.

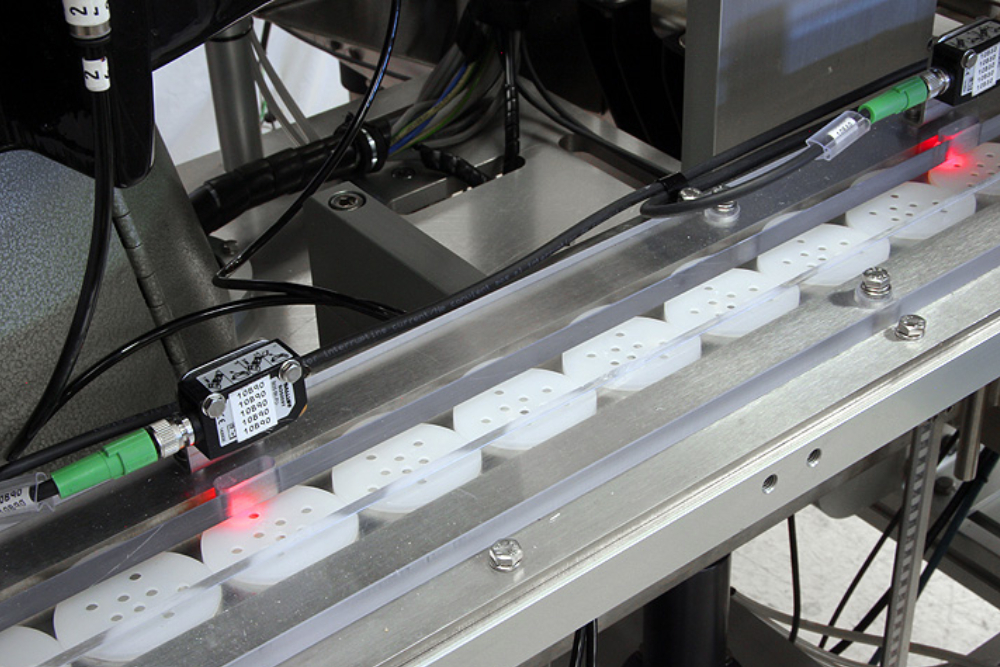

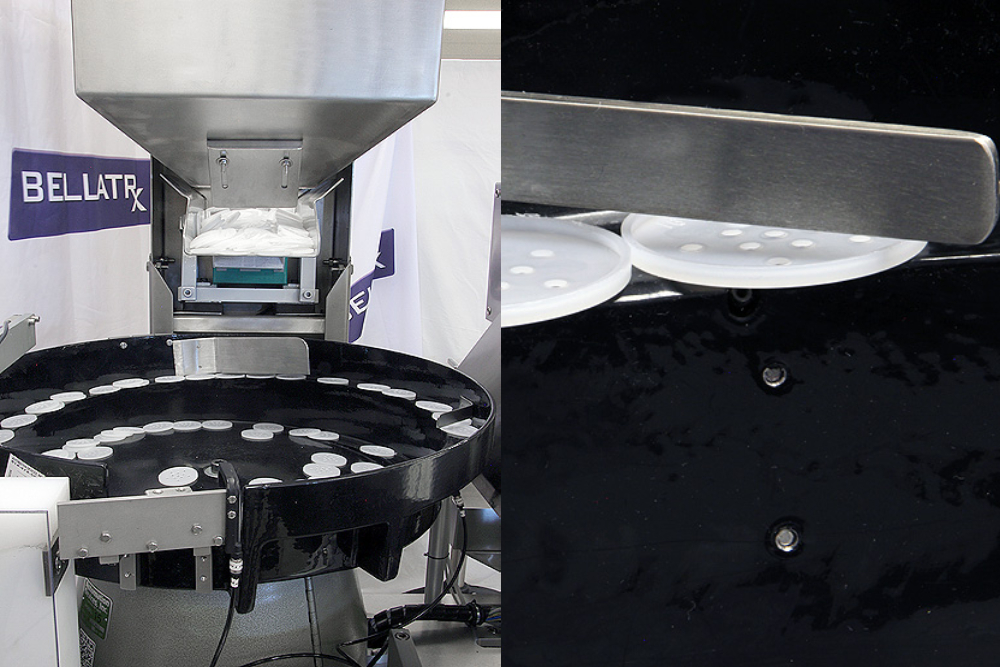

Compared with other capping equipment, the Prime Plugger is very easy to set up, operate, and run. It uses a vibratory bowl to unscramble, sort, and feed plugs to the plug application station. A pneumatic bottle gating assembly is mounted to any conveyor to index and clamp containers in place. Plugs are applied in the plug application station.

Features & Benefits:

- Chuck design squarely inserts dropper tips/stoppers onto containers

- Reject rates typically 0.5% or less

- Quick changeover with minimal adjustment points

- No adjustments are required when running

- Allen-Bradley PLC and color touchscreen

Standard Specifications:

- Speeds up to 60 cpm

- 0.5” – 8” by 12” high container range

- 5 – 30 in. lbs. application torque