Some container handling applications lend themselves to the use of robotics. Integrating pick and place robots enables companies to gain a competitive edge while maximizing productivity

Automatic Pick and Place Robotic Packaging for Unstable Containers

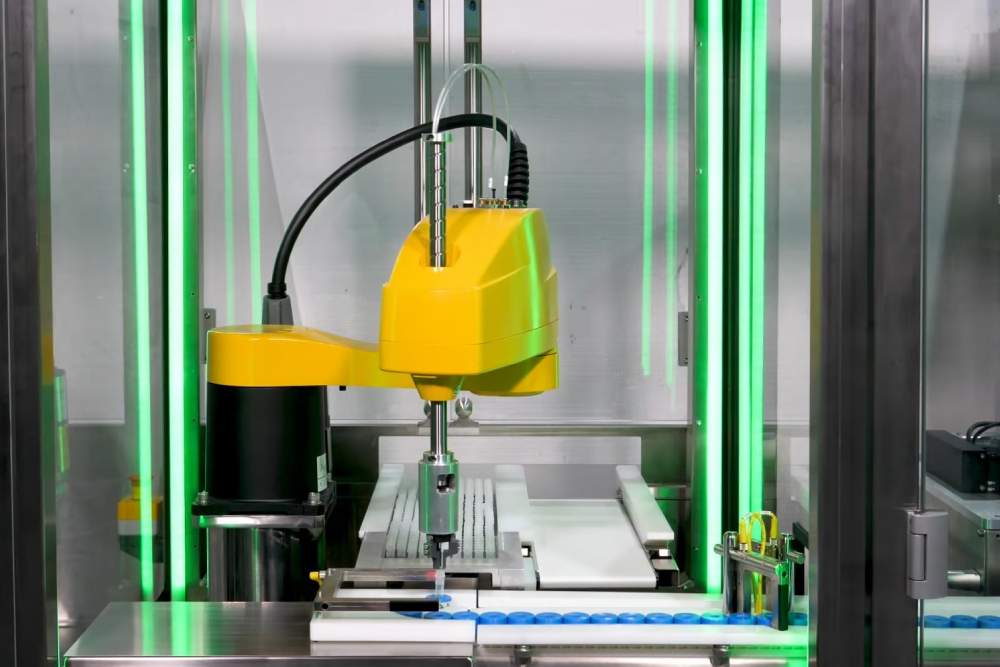

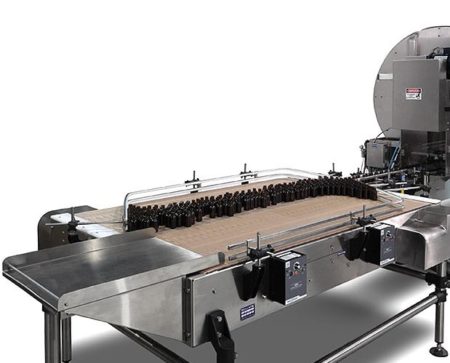

Some container handling applications lend themselves to the use of packaging robots. Automated conveyor belt systems are designed for speed and consistency, and because humans aren’t involved, improved safety is inevitable. These days robotic packaging machinery can do more than ever. Enhance your productivity with robotic packaging machinery that picks and places, packs erects, and palletizes your packaging products.

We have made advancements with our robotic packaging (Packaging Robots) for bottle handling with end-of-arm tooling, vision positioning, and robot mounting to expand the envelope where robotics can be used to replace labor-intensive applications. It’s a great way to improve the efficiency of your conveyor belt system while saving money, too.

ROBOTIC PACKAGING APPLICATIONS:

- Pick and place containers from the rotary table

- Pick and place containers from transport belts

- Pick and place containers from trays

- Placing containers into transport pucks and removing them from pucks

- Product feeding from the vibratory track, tray, conveyor, or chute

Read an interesting article here: How Robots are Revolutionizing Packaging and Processing Tasks – PMMI ProSource Directory