BellatRx offers different technologies and a wide range of automatic robotic feeders to optimize the feeding process in packaging lines.

Robotic Automatic Pick and Place Feeding System for Desiccants, Scoops, Syringes, and Measuring Cups

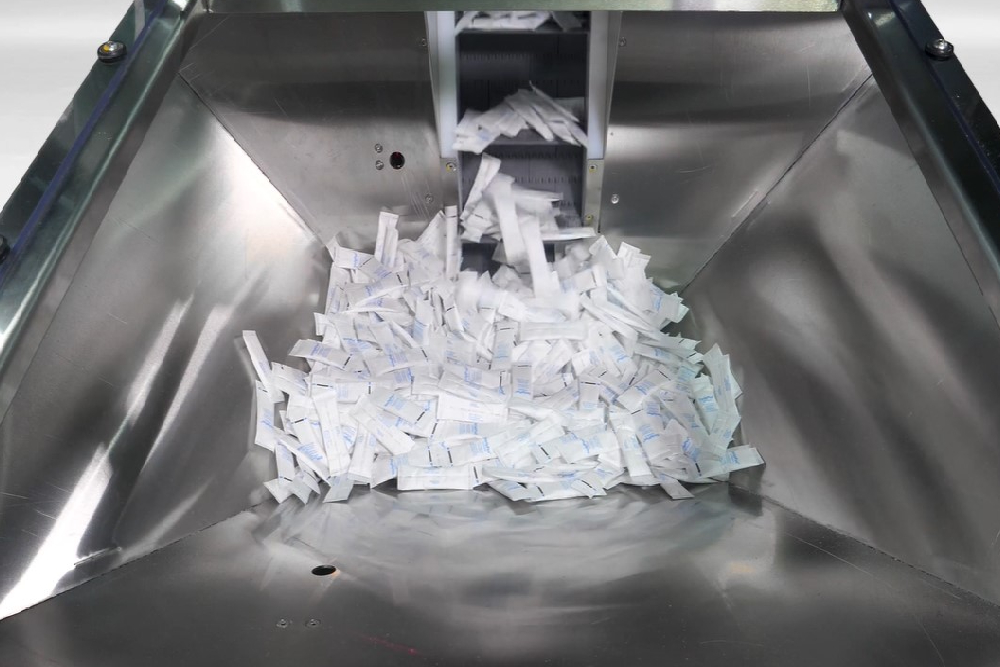

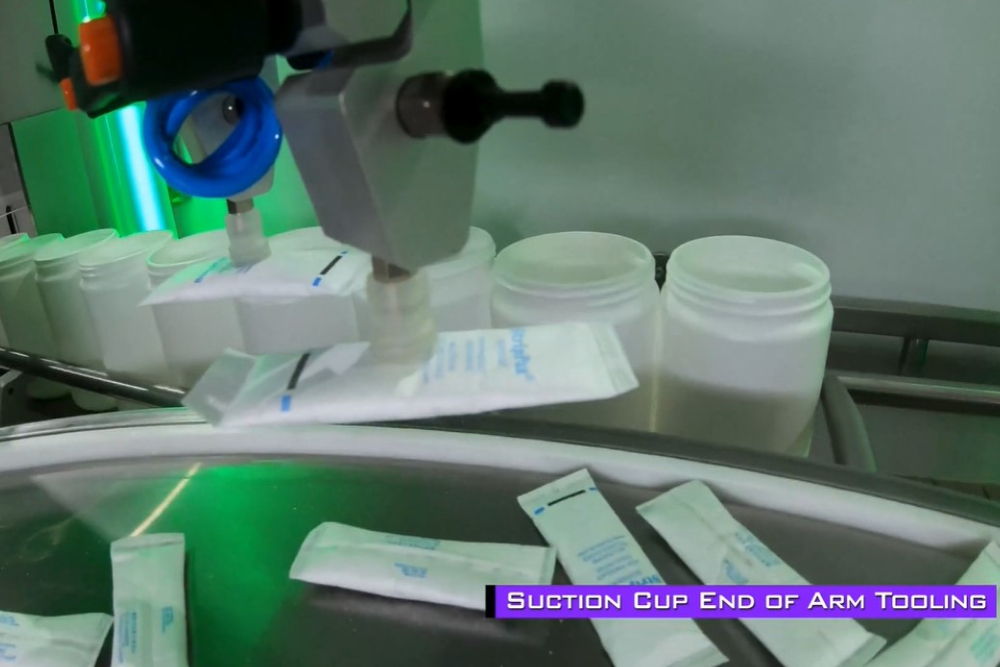

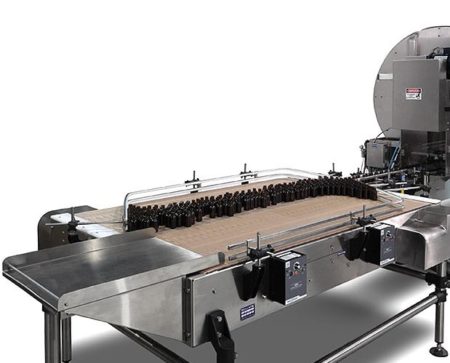

Lynx is an advanced robotic feeding system or automatic part feeder designed for bottle handling, specifically for nutraceutical and pharmaceutical packaging lines. This innovative packaging feeding system uses end-of-arm tooling, vision positioning, and robot mounting to handle various packaging parts, such as desiccants, measuring cups, scoops, syringes, and more.

What truly sets the Lynx apart is its remarkable flexibility of formats. With minimal changeover time and cost, the system can handle parts of different shapes and sizes, making it an ideal solution for companies with diverse product lines. The Lynx’s recipe selection and end-of-arm tooling eliminate the need for multiple tools and storage, making it an efficient and cost-effective solution for packaging companies. Pick-and-place systems allow a much broader product variety than traditional/mechanical systems.

The Lynx’s robotic arm technology enables it to pick and place parts quickly and accurately, with the ability to adjust to various container shapes and sizes. Its adaptability and versatility make it an excellent choice for packaging companies looking to automate their processes and increase efficiency.

Features & Benefits:

- Robotic station with suction cup end of arm tooling

- Flexible product diversity with quick changeover

- Suitable for all scoops, desiccants, dosing cups and syringe varieties

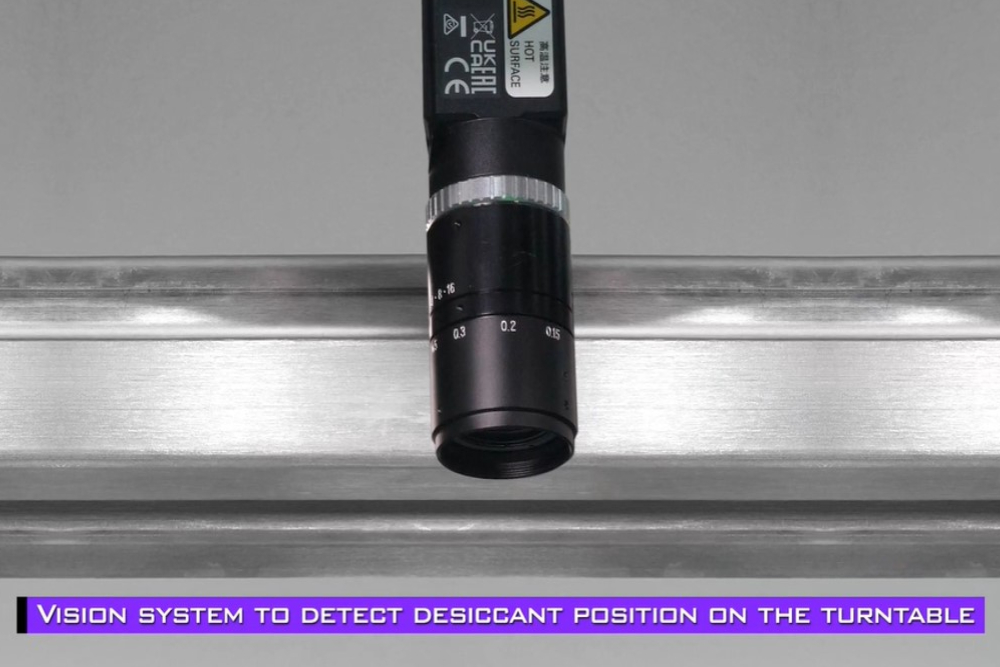

- Reliable vision and reject system

- Vision system for detecting precise parts’ position

- Pick and place from the rotary table, transport belts, trays, pucks, conveyors or chutes

- Speeds up to 60 cpm

Read an interesting article: How Robots are Revolutionizing Packaging and Processing Tasks – PMMI ProSource Directory.