Accumulation Table & Conveyor Belt Packaging Solutions

ACCUMULATION TABLE TYPES

There are three main types of accumulation tables:

- Rotary Accumulation Tables. Rotary accumulation tables are round and rotate clockwise or counterclockwise to collect, hold, pause, and release bottles as needed.

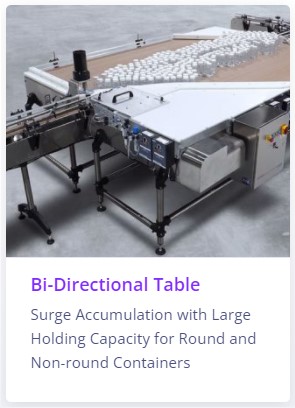

- Bi-Directional Accumulation Tables. Bi-directional accumulation tables run in two opposing directions to balance upstream and downstream production. They feature a right-angle sorter to gently sort bottles into a single line for temporary holding before they are reintroduced onto the conveyor belt.

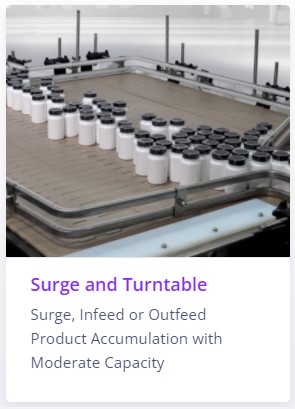

- Surge Accumulation Tables. Surge accumulation tables help maximize production output by receiving and holding bottles in the middle of a line when downstream production is moving slower than the rest of the line. Once the backup has been cleared, products are returned to the conveyor belt system.

Other styles are available, as well, depending on your production and packaging needs.

Industries We Serve:

Request A Brochure

ACCUMULATION TABLES IMPROVE PACKAGING EFFICIENCY

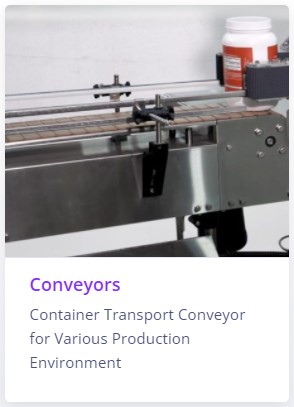

Conveyor belts are crucial to the operations of many manufacturing facilities. Their function, in a nutshell, is to move objects from Point A to Point B automatically. They’re just one component of an automated assembly and packaging line.

An accumulation table is another key piece of equipment. It is used to collect and distribute products such as bottles, cans, jars, and other containers at the beginning, middle, or end of a packaging line. What they are used for depends on where they are used.

When placed at the beginning of a packaging line, operators fill the accumulation table with bottles rather than placing them on the conveyor belt one at a time, streamlining an otherwise tedious and time-consuming process. The accumulation table sorts and discharges individual bottles onto the conveyor belt, where they are whisked away to their next stop.

An accumulation table set up in the middle of a packaging line is designed to pause items from moving down the conveyor belt system. This is helpful when objects are moving down the conveyor faster than they can be picked, and workers need time to catch up. The accumulation table features upstream gates that can be opened or closed to account for these bottlenecks. In addition, movement may be halted in the middle of the line when cooling and drying zones are needed.

Accumulation tables installed at the end of a packaging line are used to collect bottles prior to packaging and prevent them from backing up and slowing down the entire conveyor belt system. Workers can quickly and easily unload items from the accumulation table conveyor and get them packaged more efficiently.

Conveyors Belts and Accumulation Table Solutions:

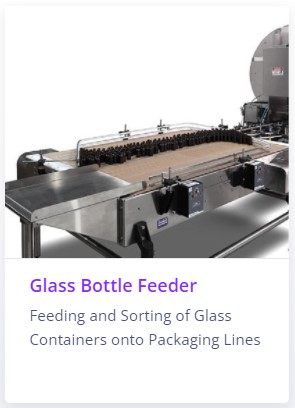

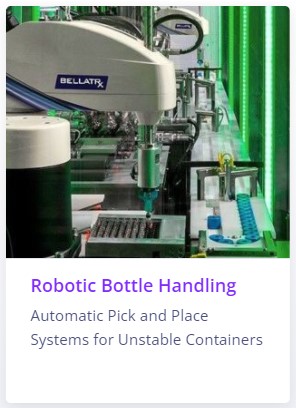

From surge table accumulation systems, conveyor belts, and bi-directional tables to high-speed bottle feeders, BellatRx has the solution you need to move products around your production line.

Conveyor belts date back to 1892 when inventor Thomas Robins developed a system for carrying coal, ores, and similar products. His designs led to the modern steel conveyor belt, though primitive wooden versions featuring bucket elevators predate Robins’ invention by a century.

Today, conveyor belts are the interlinks between machines in packaging lines, and their importance cannot be overstated. Proper container handling ensures balanced line operation; prevents splashes, spills, and jams along the line; and, when correctly designed, eases the setup and cleaning of packaging lines overall.